You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The ultimate street galant in the making? Cheekychimp's

- Thread starter Bimmubishi

- Start date

cheekychimp

Well-known member

LMFAO ... why do you think I opted for leather seats this time.

Well the last few months have been pretty hectic as you know. In addition to trying to sort out a plan of action for the car after my mechanic put himself into hospital we have been sorting out some building work at the house. We moved out to get that done and I haven't had internet for a while hence my lack of time on here.

Anyway that's all stuff for another thread. I have sourced another friend to help with the car. He has promised to get the car up and running in barebones form by around March for inspection and re-registration. It will have a pretty bare interior and dash and very few gadgets and it will probably run on a stock turbo/injectors etc. But it will run! That way I can put the interior back in and drive the car to anywhere I need to get stuff like the audio and window tinting installed. I'll also be able to take the car home and work on the interior.

This also means I can get going whilst Curtis is doing some stuff for me as he got behind when he tried the DIY amputation course!

Not exciting news exactly but at least I have a schedule now. I am happy sorting out the interior and with the car actually running I don't anticipate any real problems with most of the installation. The biggest issue is really going to be the oil system and I can put that on hold by using a stock turbo to start with whilst Aaron sorts out the new system for me.

Well the last few months have been pretty hectic as you know. In addition to trying to sort out a plan of action for the car after my mechanic put himself into hospital we have been sorting out some building work at the house. We moved out to get that done and I haven't had internet for a while hence my lack of time on here.

Anyway that's all stuff for another thread. I have sourced another friend to help with the car. He has promised to get the car up and running in barebones form by around March for inspection and re-registration. It will have a pretty bare interior and dash and very few gadgets and it will probably run on a stock turbo/injectors etc. But it will run! That way I can put the interior back in and drive the car to anywhere I need to get stuff like the audio and window tinting installed. I'll also be able to take the car home and work on the interior.

This also means I can get going whilst Curtis is doing some stuff for me as he got behind when he tried the DIY amputation course!

Not exciting news exactly but at least I have a schedule now. I am happy sorting out the interior and with the car actually running I don't anticipate any real problems with most of the installation. The biggest issue is really going to be the oil system and I can put that on hold by using a stock turbo to start with whilst Aaron sorts out the new system for me.

curtis

Well-known member

Not a bad plan of attach. This way you can get the government off your ass and break the motor in slow and find problems.

OldHairyBastard

Well-known member

Sorry Curtis but Paul had me cracking up with this one.---LOL

"This also means I can get going whilst Curtis is doing some stuff for me as he got behind when he tried the DIY amputation course!

"

Good to hear that the car will be up and running soon and you can take the family on a little boosted drive.

"This also means I can get going whilst Curtis is doing some stuff for me as he got behind when he tried the DIY amputation course!

"

Good to hear that the car will be up and running soon and you can take the family on a little boosted drive.

curtis

Well-known member

Hell I laughed to....news is I may have a finger print. /ubbthreads/images//graemlins/worthy.gif

It just want match my old one.

It just want match my old one.

Rausch

Well-known member

Quote:

The biggest issue is really going to be the oil system and I can put that on hold by using a stock turbo to start with whilst Aaron sorts out the new system for me.

Speaking of which...I need to source another test turbo. I disassembled mine, as it was leaking every time I tested the damn thing.... /ubbthreads/images//graemlins/mad.gif

The biggest issue is really going to be the oil system and I can put that on hold by using a stock turbo to start with whilst Aaron sorts out the new system for me.

Speaking of which...I need to source another test turbo. I disassembled mine, as it was leaking every time I tested the damn thing.... /ubbthreads/images//graemlins/mad.gif

Last edited by a moderator:

cheekychimp

Well-known member

No pictures yet so don't ask, but progress!

Engine is in.

Gearbox is in, together with the clutch and diffs.

GTO Rear arms are at the machine shop to modify GTO hubs to fit my rear brakes (found out I have to have a cable e-brake to pass inspection!!!)

Oil cooler and lines are in.

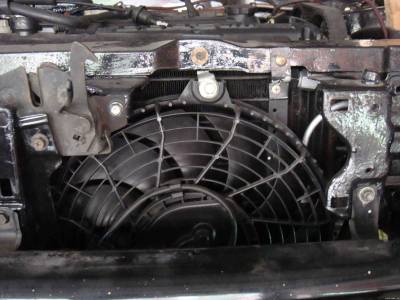

Integra DC5 fans modified to fit stock OEM mounts and in.

I am still working on a few problems with some board members, but finally there is some hope of finishing this project.

Engine is in.

Gearbox is in, together with the clutch and diffs.

GTO Rear arms are at the machine shop to modify GTO hubs to fit my rear brakes (found out I have to have a cable e-brake to pass inspection!!!)

Oil cooler and lines are in.

Integra DC5 fans modified to fit stock OEM mounts and in.

I am still working on a few problems with some board members, but finally there is some hope of finishing this project.

/ubbthreads/images/graemlins/worthy.gif On May 18, 2008, we need to celebrate the 3 year anniversary of this thread & build. Sounds like some major progress has been made /ubbthreads/images/graemlins/applause.gif. Keep us posted.

Myles

Well-known member

Quoting JB:

If someone needs a broken leg, let us know.

+1 If it's anyone in the midwest. We'll track them down. Break a few fingers so they can't type anymore.

If someone needs a broken leg, let us know.

+1 If it's anyone in the midwest. We'll track them down. Break a few fingers so they can't type anymore.

JSchleim18

Well-known member

haha I'll be down...sucks when people don't pull through

On a side note, I really wanna get a JDM Windshield Washer Fluid Reservoir with the neck and all...I snapped a bolt taking mine off the OEM location and my CUSCO Strut Bar is taking its place

I also love the interior paint you used...cleans them up really nice...would any interior paint do just as good a job?...best of luck with the build and I really hope it goes smooth! /ubbthreads/images/graemlins/applause.gif

On a side note, I really wanna get a JDM Windshield Washer Fluid Reservoir with the neck and all...I snapped a bolt taking mine off the OEM location and my CUSCO Strut Bar is taking its place

I also love the interior paint you used...cleans them up really nice...would any interior paint do just as good a job?...best of luck with the build and I really hope it goes smooth! /ubbthreads/images/graemlins/applause.gif

Last edited:

cheekychimp

Well-known member

I wish you had told me earlier, you could have had mine, it won't fit in the stock location, now that I've welded in the strut tower supports. I'll see if I can find you one.

Last edited:

cheekychimp

Well-known member

Progress Report

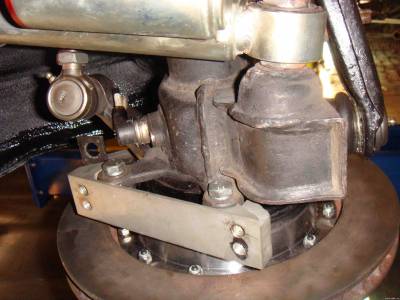

Solution to keeping E brake whilst using 4-Pot AP rear calipers ...

This is the old Selby Sway Bar. The 26mm Whiteline bar is at the "machine" shop being re-bent, trimmed and having the bolt holes welded in and then re-drilled for oem endlinks.

Intercooler is on and fits behind RS JDM Bumper ... just!

Honda Type R Fans FTMFW!!!

Almost done under here ... Harry's scattershield still to be fitted.

Front brakes are now being sorted. Needed $580 of new rotor hats and 'minimal' changes to the caliper brackets. Wheels are a +35 offset so it seems some 'old school' genuine sheet metal fender flares are inevitable.

Solution to keeping E brake whilst using 4-Pot AP rear calipers ...

This is the old Selby Sway Bar. The 26mm Whiteline bar is at the "machine" shop being re-bent, trimmed and having the bolt holes welded in and then re-drilled for oem endlinks.

Intercooler is on and fits behind RS JDM Bumper ... just!

Honda Type R Fans FTMFW!!!

Almost done under here ... Harry's scattershield still to be fitted.

Front brakes are now being sorted. Needed $580 of new rotor hats and 'minimal' changes to the caliper brackets. Wheels are a +35 offset so it seems some 'old school' genuine sheet metal fender flares are inevitable.

Last edited:

rheckert

Well-known member

Good to see you are still making progress 3 years after this thread started.

curtis

Well-known member

You do own a car. /ubbthreads/images/graemlins/grin.gif

Ok whats the brace in the picture thats under the IC and beside the JDM drivers side IC pipe.

Also I see subframe connectors and looks to be a one piece driveshaft. /ubbthreads/images/graemlins/devil.gif

Ok whats the brace in the picture thats under the IC and beside the JDM drivers side IC pipe.

Also I see subframe connectors and looks to be a one piece driveshaft. /ubbthreads/images/graemlins/devil.gif

curtis

Well-known member

Also the front bar design will work with the IC. /ubbthreads/images/graemlins/grin.gif

Still need a top view picture of the IC looking down at it with no grill or lights installed.

Still need a top view picture of the IC looking down at it with no grill or lights installed.

cheekychimp

Well-known member

Okay, I'll try to get some better pictures.

The subframe connectors you already knew about. Driveshaft is actually 2 piece rather than 3 piece, the final section is still OEM steel but the aluminium section from the shiny connector you can see down to the transmission/transfer case still shaves off a fair bit of weight.

The brace is a weird piece. Ken (the guy you can see fiddling with the bumper and intercooler) got this off a rally car. It is actually used to mount the heavy steel skid plate under there. He refused to mount the plate because it weighs so much but said the bar made such a huge difference to handling that he refused to part with it. I ended up buying the skid plate from him and 'borrowing' the brace so I could have this stainless steel version made from it. It is more weight up front but I wanted the skid plate. I've run over some big frickin' rocks that construction site trucks dropped on the highway before and with the cost of this engine and tranny I want some insurance for the future.

The subframe connectors you already knew about. Driveshaft is actually 2 piece rather than 3 piece, the final section is still OEM steel but the aluminium section from the shiny connector you can see down to the transmission/transfer case still shaves off a fair bit of weight.

The brace is a weird piece. Ken (the guy you can see fiddling with the bumper and intercooler) got this off a rally car. It is actually used to mount the heavy steel skid plate under there. He refused to mount the plate because it weighs so much but said the bar made such a huge difference to handling that he refused to part with it. I ended up buying the skid plate from him and 'borrowing' the brace so I could have this stainless steel version made from it. It is more weight up front but I wanted the skid plate. I've run over some big frickin' rocks that construction site trucks dropped on the highway before and with the cost of this engine and tranny I want some insurance for the future.

Rausch

Well-known member

As discussed... The rear brake set-up is a PHENOMINAL idea. Using the GTO arms, and 'hats' if you will. Looking forward to seeing more specifics. /ubbthreads/images/graemlins/applause.gif

What width wheels are they? Must be pretty wide is a +35 doesn't fit?