EfiniX

Well-known member

I met with EHMotorsports yesterday and we knocked out a dodge mod BoV in about 3 hours. The result of the mod was interesting. I actually noticed I was still getting a bit of flutter at higher boost levels. This behavior abruptly stopped when I blew my recirculation hose clean off the intake. Venting to atmosphere resulted in no flutter whatsoever. My BoV hose has a nasty bend in it, the result of using too-short of a connection. I'm guessing the tight bend the hose had to make to get into the intake pipe (right after the MAF, of course) was creating just enough back-pressure to flutter the valve. I'm going to fix this today with some new hose and report back. I'm guessing this issue goes with a new dump hose.

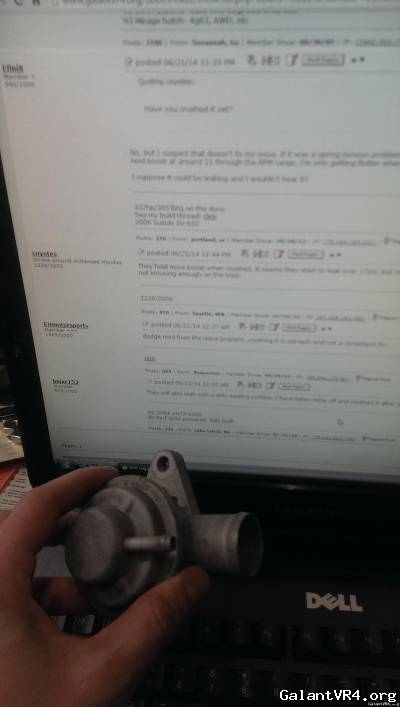

My stock BoV

You can see the stock valve was crushed.

I noticed the VR4 board was open on Evan's shop computer. I would say his suggestion of doing the Dodge Mod was excellent advice!

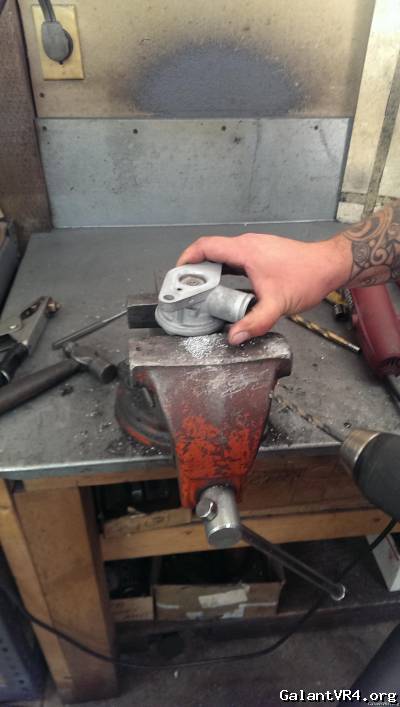

Cleaned, sand-blasted, rinsed and ready for modding. Evan had a stock BoV already sitting around, so we Dodge-modded that valve and I gave him my valve to mod later.

I decided to use a cap bolt so we wouldn't have to worry about filling or filing to get a hose to seal.

Evan has a lathe, which makes drilling out the cap bolt easy and precise. I've seen people with a vice and a hand drill and I have to imagine you break a few bits and a few bolts before getting it right.

He lathed the nipple on free-hand. Definitely something he's done before.

Now to drill-out and tap the valve.

Sealing off the stock intake pressure hole

Tapping the turbo outlet

The new valve painted and installed

Turbo outlet line installed

And of course, proof that it is, indeed, blowing off /ubbthreads/images/graemlins/smile.gif

My stock BoV

You can see the stock valve was crushed.

I noticed the VR4 board was open on Evan's shop computer. I would say his suggestion of doing the Dodge Mod was excellent advice!

Cleaned, sand-blasted, rinsed and ready for modding. Evan had a stock BoV already sitting around, so we Dodge-modded that valve and I gave him my valve to mod later.

I decided to use a cap bolt so we wouldn't have to worry about filling or filing to get a hose to seal.

Evan has a lathe, which makes drilling out the cap bolt easy and precise. I've seen people with a vice and a hand drill and I have to imagine you break a few bits and a few bolts before getting it right.

He lathed the nipple on free-hand. Definitely something he's done before.

Now to drill-out and tap the valve.

Sealing off the stock intake pressure hole

Tapping the turbo outlet

The new valve painted and installed

Turbo outlet line installed

And of course, proof that it is, indeed, blowing off /ubbthreads/images/graemlins/smile.gif

Last edited: