Quote:

I realized that I wasn't going to be much help for your cost sharing program, but I don't want to go back to a three inch intake. I'll PM you on this aspect.

Drop me a line, I'll set ya up.

Quote:

As for the other stuff, you sound like you have been knocking around on the WI forums as well, so what have you gone with a full aquamist kit or something you designed yourself using a Shurflo. I kind of like the simplicity of the Shurflo but I know the diagnostics of the aquamist kit doesn't work so well with a high pressure pump. A lot of guys have had issues with aquamist pumps breaking but Richard says that whilst most were replaced, a lot of damage occurred because they were mounted in ways or locations that weren't recommended or allowed to run dry. If that's the case it seems a bit unfair to blame the pump design. Would you blame a bearing or piston manufacturer if you ran your engine without oil in it and it seized?

Yep, I've been on Aquamist's forum for quite some time now. The pre-compressor injection thread

REALLY got the gears turning in my head and spurred all this on.

As for my system, right now the only Aquamist parts are the nozzles in the manifold. I really like the FIA2 and HSV, and as the funds allow I'm going to integrate these into my system. And yes, my system is kind of Frankensteined together, but it works great as-is and all the parts and pieces are dead-reliable.

I like all of the Aquamist parts, except for the pump. I wouldn't run that thing if you

paid me to. A buddy with a Stealth TT had one fail on him and he popped a head gasket because of it. Not catastrophic, but could have been. It's almost as if you look at those things the wrong way they'll fail. The Shurflo pump gets my nod, it's a beast of a pump! It can flow all the water I'll ever need it to, can be run dry for short periods of time and it repressurizes the system in under a second. The only downside is that it doesn't work with the blocked flow diagnostics of the Aquamist system. For the reliability of the Shurflo pump I'll give up that feature.

Quote:

As for direct port injection, how do you have you failsafes setup. Are you just monitoring flow in the main supply line until it branches into the four ports or do you have a flow detector on each nozzle line at the ports?

For failsafes on the nozzles going into the manifold, I've got a stainless solenoid and Aquamist check valve right before the line branches off to the four jets. Again, not cheap but I didn't want to cut any corners or risk a methanol backfire.

Also, I've kicked around the idea of integrating a flow sensor and Aquamist DDS3 system, but again it's funds-limited.

Quote:

Finally how is your system set up with the 5 nozzles. Are you going to spray simultaneously or at different points for the compressor and manifold? And are the four port nozzles the same size?

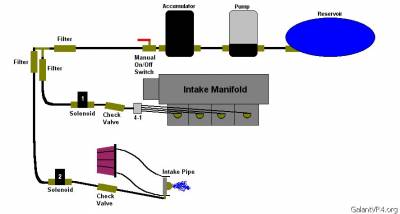

The current setup via my pimp MS Paint skillz:

The reservoir is a

3 gallon fuel cell from Summit and has a

GM 0-90 ohm level sensor and

gauge integrated into it. The pump is a

Shurflo 100 psi unit and the

24oz accumulator is from Shurflo also. I had kicked around the idea of a smaller "water hammer," but I like the larger Shurflo accumulator because it prevents the pump from constantly running and the fact that it's designed to work with the Shurflo pump. The pressure switch on the pump is set so it turns off at 105 psi and kick back on at 88-90 psi. A few strokes of the pump and the system is right back up to pressure.

The manual on-off valve is a simple ball-valve from the local hardware store. I believe it was designed for propane use, but it works great for this application, seals perfectly and is rated to 600 psi. Don't think I'll be going anywhere near that. /ubbthreads/images/graemlins/wink.gif The filters are 40 & 90 micron inline units from McMaster-Carr (part #s 98355K841 & 98355K842 respectively). The solenoids are from McMaster-Carr also and are wired in to two Hobbs switches set to 15 psi for the direct port nozzles and 22 psi for the pre-compressor nozzle (haven't activated this one yet).

The

check valves are from Aquamist and have a crack pressure of ~15 psi. Though they're not 110% needed, I prefer to have them in there to prevent any water/methanol from getting sucked into the engine while under vacuum.

The

nozzles in the manifold are from Aquamist also. Right now I'm running four .4mm nozzles, but may up that as boost increases. The

nozzle in front of the compressor is a PJ15 from Bete. Like I said, it was meant for fogging purposes but it works great for this.

Quote:

P.S. A third reason for injecting pre compressor you haven't mentioned is that it has actually been shown to extend or shift the compressor map giving rise to increased flow at the top end.

Yep, this is my main reason for injecting pre-compressor and what got my mind going on all this craziness. Running higher boost levels and injecting pre-compressor will bring the efficiency back to the left on the compressor map. I can only wring so much out of this 50-trim wheel before it starts to blow

really hot air. And once I've tapped that resource I guess there'll be no choice but to sneak a Red in there... /ubbthreads/images/graemlins/devil.gif