If you need any flanges made let me know. I can have any flange made out of any material with tolerance of a thousandth. My prices are also very reasonable.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quote:

so its not the plenum size/design and runner entry location/design that does it?

How are you going to change the runner entry location? To answer your question the majority of the problem has to do with a properly pulse tuned intake.

so its not the plenum size/design and runner entry location/design that does it?

How are you going to change the runner entry location? To answer your question the majority of the problem has to do with a properly pulse tuned intake.

ok

CutlassJim

Well-known member

Quote:

problem here is runner taper. if you cant get anything bigger they will probably work, but they wont be optimal because you wont be able to put much, if any, taper into the runners.

Since you've mentioned your involvement with Chevy's this statement makes sense. I am heavy into Turbo Buick's and most American engines intake runners start to taper right from the plenum but if you look at the stock manifold design on a DSM there is actually no taper in the runners at all. All the taper is done in the head right before the valves.

The same with most after market intake manifolds I've seen as well. They have huge runners that squish RIGHT before they hit the head just so that they port match up nicely.

If your going to stay under 400 crank HP and under 7k RPM and actually drive your car then the stock manifold will work perfect. Anything more than that is starting to give up ease of drivability for not much gain in power IMHO. If you want a little more power the EVO 3 manifold has a larger volume plenum (not by much) and MUCH shorter runners that I think would aid in power above 5k RPM considerably but not as drastic of a change in powerband as a sheet metal.

For my street engine in the Galant I actually want to build a 6-bolt with 95 pistons and a 2G head. I also really want to try out FP's new 18G. Car should be 350 WHP easy on pump running around 22 psi daily and hopefully be at said boost around 3500 RPM. With some timing it won't a complete dog off boost either. Which is exactly what I'm looking for in a DD.

If the engine is going to be pure drag that dismiss this entire post. /ubbthreads/images//graemlins/smile.gif

P.S. I also agree that plenum volume should be in the range of 1.2-1.5 times the displacement of the motor. An EVO 3 manifold with a modified, read larger, plenum would be a great top end design with not a lot of fab needed.

problem here is runner taper. if you cant get anything bigger they will probably work, but they wont be optimal because you wont be able to put much, if any, taper into the runners.

Since you've mentioned your involvement with Chevy's this statement makes sense. I am heavy into Turbo Buick's and most American engines intake runners start to taper right from the plenum but if you look at the stock manifold design on a DSM there is actually no taper in the runners at all. All the taper is done in the head right before the valves.

The same with most after market intake manifolds I've seen as well. They have huge runners that squish RIGHT before they hit the head just so that they port match up nicely.

If your going to stay under 400 crank HP and under 7k RPM and actually drive your car then the stock manifold will work perfect. Anything more than that is starting to give up ease of drivability for not much gain in power IMHO. If you want a little more power the EVO 3 manifold has a larger volume plenum (not by much) and MUCH shorter runners that I think would aid in power above 5k RPM considerably but not as drastic of a change in powerband as a sheet metal.

For my street engine in the Galant I actually want to build a 6-bolt with 95 pistons and a 2G head. I also really want to try out FP's new 18G. Car should be 350 WHP easy on pump running around 22 psi daily and hopefully be at said boost around 3500 RPM. With some timing it won't a complete dog off boost either. Which is exactly what I'm looking for in a DD.

If the engine is going to be pure drag that dismiss this entire post. /ubbthreads/images//graemlins/smile.gif

P.S. I also agree that plenum volume should be in the range of 1.2-1.5 times the displacement of the motor. An EVO 3 manifold with a modified, read larger, plenum would be a great top end design with not a lot of fab needed.

JNR that is exactly what I am trying to do is something different. Can you explain what a true dual runner intake is, as well as a dual plane unit? Just the theory of them not your design. Also what is different on the 2G head are the flanges you have able to be retrofitted?

Is .125" or 1/8" 6061 sheet thick enough? Or should it be thicker.

1/8" 6061 should be fine depending on how you design it. Their are some sections I would use just a tad thicker depending on the design just from what I have seen with some intake manifolds and FMIC's that use 1/8" everywhere that end up having problems splitting.

IF I was to make one, I would probably make it out of 5052 for various different reasons but that's just me. I'd also anodize it when I was finished.

IF I was to make one, I would probably make it out of 5052 for various different reasons but that's just me. I'd also anodize it when I was finished.

As a general rule: The longer, smaller diameter runners are beneficial to low and mid-range power (mainly torque) and short, larger diameter runners are for higher rpm power (horsepower).

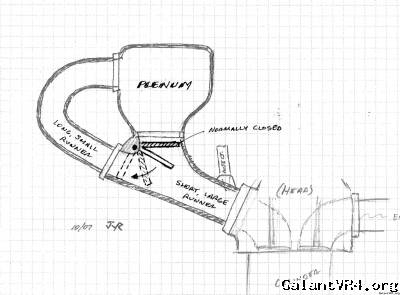

so, a true dual runner intake would have a 'flapper' that would close off the short/large runners until a higher rpm/load (depending on how you set it up) and when it hits that variable (rpm), it opens the short/large runners and closes the long/small runners, giving it the best of both worlds...In a good design, it would have a 'fail closed' on the short runners, so in the event of failure, it goes thru the long, giving it better drivability, etc.

A Cyclone manifold is a psuedo dual runner design, with compromie...Yes, it shuts off the shorter runners, but when it opens, it still uses the long runners and the diamter of the shorter runners is not that much bigger.

(I'll see if I can find a good pictorial of this)

so, a true dual runner intake would have a 'flapper' that would close off the short/large runners until a higher rpm/load (depending on how you set it up) and when it hits that variable (rpm), it opens the short/large runners and closes the long/small runners, giving it the best of both worlds...In a good design, it would have a 'fail closed' on the short runners, so in the event of failure, it goes thru the long, giving it better drivability, etc.

A Cyclone manifold is a psuedo dual runner design, with compromie...Yes, it shuts off the shorter runners, but when it opens, it still uses the long runners and the diamter of the shorter runners is not that much bigger.

(I'll see if I can find a good pictorial of this)

What are the plus and minuses of using the 5*** series that you suggest? I dont know much about the properties of the two.

OK, here's a crude sketch, to give you an idea...note it is not meant to represent any proportions, actual workings of the 'flapper', etc. and should be treated only as a diagram...also, it is not 4G63 specific.

BTW - can anybody convert a PDF or TIF imagine into JPG, for a better quality? I don't have any graphics programs here! Edit, nevermind, it came out *OK* for now; just don't blow it up, lol.

BTW - can anybody convert a PDF or TIF imagine into JPG, for a better quality? I don't have any graphics programs here! Edit, nevermind, it came out *OK* for now; just don't blow it up, lol.

Last edited:

Rausch

Well-known member

^sure can, but that one is a jpeg. you got another one?

edit:NVM /ubbthreads/images//graemlins/rofl.gif

edit:NVM /ubbthreads/images//graemlins/rofl.gif

Last edited by a moderator:

Dialcaliper

Well-known member

Actually, a lot of modern n/a cars use dual stage, or even triple stage intake manifolds. On a dual stage, the fact that both runners are open is intentional. You don't get the same oomph at high end that you would from a large single short runner, but having two different runners open actually gives you *two* additional wave tuning frequencies, not just the one from the short runners. That's why the cyclone opens around 4700-5000 RPM instead of waiting until much higher RPM (6000-7000). There's not good way to have a rapid changeover without cutting off airflow and creating funky effects. The extra runners have to shut off at low RPM so that the intake velocity isn't too slow, which would hurt low end torque. At high RPM, there's enough airflow to fill both sets up runners and still keep the speed up.

So ultimately, the cyclone should give you a bit more low end torque than the stock manifold, and a total of 3 tuned RPM ranges, but because of design comprimises, it will still be inferior at the top end than a single fixed short runner design. A Triple stage intake would give you either 5 modes or 6 modes, depending on how it's designed (two runners open at once or all three open)

If you had larger short runners and a second set of butterflies to close the short runners, you'd have better top end, but your midrange would suffer during the changeover period.

The other way to do a multi-stage intake is to have adjustable trombones (probably stepper motor driven, or vacuum driven against a spring with a ) to increase the runner length at low rpm and shorten it at high RPM, but the compromise in that situation is that you can't really shrink the runner diameter at low RPM.

I don't think anyone's come up with a truely variable geometry intake yet that can vary both adjust length and runner diameter. If they have, it's either custom, very expensive, or both.

Quote:

As a general rule: The longer, smaller diameter runners are beneficial to low and mid-range power (mainly torque) and short, larger diameter runners are for higher rpm power (horsepower).

so, a true dual runner intake would have a 'flapper' that would close off the short/large runners until a higher rpm/load (depending on how you set it up) and when it hits that variable (rpm), it opens the short/large runners and closes the long/small runners, giving it the best of both worlds...In a good design, it would have a 'fail closed' on the short runners, so in the event of failure, it goes thru the long, giving it better drivability, etc.

A Cyclone manifold is a dual runner design, with compromise for the sake of simplicity...Yes, it shuts off the shorter runners, but when it opens, it still uses the long runners and the diameter of the shorter runners is not that much bigger.

(I'll see if I can find a good pictorial of this)

So ultimately, the cyclone should give you a bit more low end torque than the stock manifold, and a total of 3 tuned RPM ranges, but because of design comprimises, it will still be inferior at the top end than a single fixed short runner design. A Triple stage intake would give you either 5 modes or 6 modes, depending on how it's designed (two runners open at once or all three open)

If you had larger short runners and a second set of butterflies to close the short runners, you'd have better top end, but your midrange would suffer during the changeover period.

The other way to do a multi-stage intake is to have adjustable trombones (probably stepper motor driven, or vacuum driven against a spring with a ) to increase the runner length at low rpm and shorten it at high RPM, but the compromise in that situation is that you can't really shrink the runner diameter at low RPM.

I don't think anyone's come up with a truely variable geometry intake yet that can vary both adjust length and runner diameter. If they have, it's either custom, very expensive, or both.

Quote:

As a general rule: The longer, smaller diameter runners are beneficial to low and mid-range power (mainly torque) and short, larger diameter runners are for higher rpm power (horsepower).

so, a true dual runner intake would have a 'flapper' that would close off the short/large runners until a higher rpm/load (depending on how you set it up) and when it hits that variable (rpm), it opens the short/large runners and closes the long/small runners, giving it the best of both worlds...In a good design, it would have a 'fail closed' on the short runners, so in the event of failure, it goes thru the long, giving it better drivability, etc.

A Cyclone manifold is a dual runner design, with compromise for the sake of simplicity...Yes, it shuts off the shorter runners, but when it opens, it still uses the long runners and the diameter of the shorter runners is not that much bigger.

(I'll see if I can find a good pictorial of this)

Last edited:

Rausch

Well-known member

^ didn't Bimmer have a variable length intake runner set up? no diameter change, but runner length?

Dialcaliper

Well-known member

The most commonly available aluminums these days are probably 2024, 5052 and 6061.

A lot of BMWs have multi-stage intakes. The 330i I think has a triple, and some of the pricer ones might have variable length runners.

A surprising number of cars have them these days. A lot of the fancy names for engines actually refer to it. (Mazda "VICS/VRIS", Porche "VarioRam", Ford "Duratec", even Hondas and a whole slew of other brands that didn't name the engine after it.

click

Edited: Yeah, I meant 5052, not 5054

A lot of BMWs have multi-stage intakes. The 330i I think has a triple, and some of the pricer ones might have variable length runners.

A surprising number of cars have them these days. A lot of the fancy names for engines actually refer to it. (Mazda "VICS/VRIS", Porche "VarioRam", Ford "Duratec", even Hondas and a whole slew of other brands that didn't name the engine after it.

click

Edited: Yeah, I meant 5052, not 5054

Last edited:

I think you mean 5052, 5054 is not that common, at least on this coast it's not.

Rausch

Well-known member

^ oh yeah, the SVT has a variable intake...oops. /ubbthreads/images//graemlins/banghead.gif

no production variable diameter though, eh?

no production variable diameter though, eh?

No doubt the way I drew the sketch would not work, as you mentioned the changeover to completely off to on would cause some turbulence, etc...However, I think with the right design and/or progressive linkage, it could be done.

There was an aftermarket Ford "5.0" manifold (kind of like the GT-40) in the early 90's that had a neat approach to the dual runner design, but I can't seem to find it right now...And, yeah, there have been a few factory examples, but I think a true functioning manifold 'design' is out there and IMO, give you some great overall results.

There was an aftermarket Ford "5.0" manifold (kind of like the GT-40) in the early 90's that had a neat approach to the dual runner design, but I can't seem to find it right now...And, yeah, there have been a few factory examples, but I think a true functioning manifold 'design' is out there and IMO, give you some great overall results.

Dialcaliper

Well-known member

Now that I think about it, one way to circumvent the variable diameter problem is what Honda did with VTEC - having a low-lift cam profile doesn't help you with runner airflow velocity, but it does help with air velocity into the cylinder, which helps your low end torque (maybe not as much as having the airflow velocity through the whole runner)

Quote:

^ oh yeah, the SVT has a variable intake...oops. /ubbthreads/images//graemlins/banghead.gif

no production variable diameter though, eh?

Quote:

^ oh yeah, the SVT has a variable intake...oops. /ubbthreads/images//graemlins/banghead.gif

no production variable diameter though, eh?