This is the first time I've done this, so feel free to add to or correct my info.

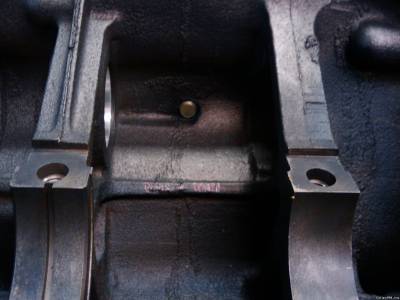

When you install an OEM or Eagle 100mm stroker crank the stroke is soo long that the rods will touch the block as well as the main caps. This is how you clearance/grind away the block to accept this extra stroke. SEE PICS

It has been discussed that doing this to the main caps MAY affect the rigidity of the bottom end. Some people use a support girdle(kigglyracing) to help remedy this. You should search/read and decide for yourself if you would like to use a main journal girdle.

Oil squirters are also a problem. With the longer stroke the piston comes down farther and can come in contact with the squirter tip. There are two ways of fixing this 1: carefully bend the oil squirter tips down. 2: Use evo8-9 oil squirters. Evo oil squirters are shapped in a way that requires no modification.

NOTE:If you're smart you should do the grinding before you take it to the machine shop because they clean it thoroughly. I didn't know this so I had to be carefull not to get shavings in the netheregions of my block. I used a shop vac to suck the shavings as I was grinding as well as a bunch of rags

So you draw a line from the center of the bore and out 3/4" each side(you'll end up with 1.5" to grind away)

shop vac sucking while I grind

The main caps are roughly 13mm thick. I shaved around 5-6mm off

When you install an OEM or Eagle 100mm stroker crank the stroke is soo long that the rods will touch the block as well as the main caps. This is how you clearance/grind away the block to accept this extra stroke. SEE PICS

It has been discussed that doing this to the main caps MAY affect the rigidity of the bottom end. Some people use a support girdle(kigglyracing) to help remedy this. You should search/read and decide for yourself if you would like to use a main journal girdle.

Oil squirters are also a problem. With the longer stroke the piston comes down farther and can come in contact with the squirter tip. There are two ways of fixing this 1: carefully bend the oil squirter tips down. 2: Use evo8-9 oil squirters. Evo oil squirters are shapped in a way that requires no modification.

NOTE:If you're smart you should do the grinding before you take it to the machine shop because they clean it thoroughly. I didn't know this so I had to be carefull not to get shavings in the netheregions of my block. I used a shop vac to suck the shavings as I was grinding as well as a bunch of rags

So you draw a line from the center of the bore and out 3/4" each side(you'll end up with 1.5" to grind away)

shop vac sucking while I grind

The main caps are roughly 13mm thick. I shaved around 5-6mm off