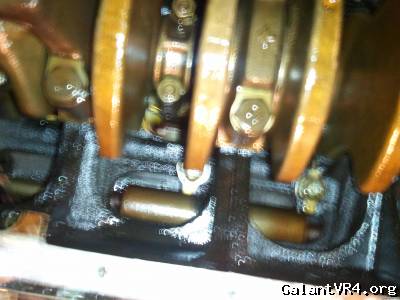

/ubbthreads/images/graemlins/dunno.gifHello to all who replied to my last post props to all as i finaly got the tranny removed from the motor . After taking the oil pan off I dont see anything that would cause the motor to cease but the bottom of the pan has a bunch of copper color shavings along with some old silicon. Is this a toasted baring? well look at the pics and let me know what you think? thanks everyone /ubbthreads/images/graemlins/worthy.gif

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barnes

Well-known member

Well. Might help to know which bearings are actually bad. Take pictures as you keep tearing it apart and let us know exactly which bearings died.

BrandonEchols

Well-known member

WTF does this even mean?

BrandonEchols

Well-known member

No, the OP's thread title and post.

1st question I have to ask is what happen? Did not turn over won't start? What caused u to come to the conclusion that it did this?

2nd question did u turn the crank to c if it still turns?

3rd question did u maintain oil change filter etc?....

2nd question did u turn the crank to c if it still turns?

3rd question did u maintain oil change filter etc?....

im sory I have all these questions answerd in another post... but I will give a quick run down.. when I bought the car for 3500 back in late Sep. it was ok but had no real power.. after some general troubleshooting I found it needed a fuel pressure reg... and there was a massive boost leak at the exaust manifold. After I reair these items with the help of Michael.. (BOOSTEDINAZ) and everyone on here. I was starting to feel better. After about 2 weeks of normal driving I started to hear a tapping from the engine when coming down in rpm and when going up as well but woud quiet at around 2200 rpm .. I started troubleshooting again .. could not find anything after trying the vibration tech listening through a long stick on the block ect... trying to see if it was on top or bottom .. it seemed to a loud lifter .. the noise got worse and worse .. wher at idle you could not hear anything really... and when you rev it up man was it loud so I stopped driving it for awhile . I then figured I would try an oil change to a lower viscosity oil 5-w30 and a new filter of course to see if it would clean the damn lifters .. no such luck again at idle it reved loud and even worse . so I parked it to see what my next move was .. about a month ago I pulled it out of the garage after warm up and pulled it into my drive way to clean my garage and when I gave it some gas to make it over the hump. it died and would not start .. just sat there and clicked @ the started. I thought it was the battery so I jumed it ... no deal, then I pulled the timing belt top cover and noticed the cams did not even move a little, so i jacked up the car and tried to pull on the crank .. no movement ... On first inspection looking in the spark plug holes all the pistons appear to be in the right stroke , so maybe not a rod, then it was just time . I guess everyone befor me except for Michael must have just beat the hell out of her and she is tired @ 175k ,, pulled the engine and getting prepped for a possable rebuild .. after i figure out what is stuck or why its frozen.. Keep in mind just looking at my spelling and my typing I suck at it and this is probably hard to read and im a nub @ 31 years of age so Im probably spend to much more money getting her fixed up since Im sure ive lost some bolts already and took very limited pics when removing the motor .. But i love the car always wanted one and I just dont care so with the go ahead from my wife it will be fixed and on the road in march for the gvr club meeting here in AZ thats if i dont blow myself up first ... thanks again to all who try to help me and who dont need like 5 beers just to read this /ubbthreads/images/graemlins/worthy.gif

SmoothCustomer

Well-known member

Are you talking about the missing belt? It's the balance shaft belt and it was deleted. Someone at least tried to do it right because there is rtv on that tensioner bolt.

fuel

Well-known member

the balance belt and belt tensioner are missing, it looks like a shorter bolt has been put back in place with gasket goo or JB weld. The left side balance shaft still looks to be in place while I could only assume the balance shaft run off the oil pump has been machined off or the weights machined down to the shaft.

great this explains why my car shook like hell I thought it was the damn urathane firewall mount /ubbthreads/images/graemlins/banghead.gif I do believe I liked this feature to keep the ratting in my car to a minumum... I might just try to fix this as well after I find out what happen to the motor first .. next is the head maby this sunday I can pull it off and see whats what...

fuel

Well-known member

yeah I would pull the head off and see if the bottom end can still spin. It could have been overheated and one or more of your pistons expanded but with what's in the sump it more than likely is a run bearing, but I don't think that usually results in a total seizure unless it was run completely dry of oil.

turbowop

Well-known member

Quoting Drdamm21:

great this explains why my car shook like hell I thought it was the damn urathane firewall mount /ubbthreads/images/graemlins/banghead.gif I do believe I liked this feature to keep the ratting in my car to a minumum... I might just try to fix this as well after I find out what happen to the motor first .. next is the head maby this sunday I can pull it off and see whats what...

The vibrating was probably caused by the urethane mount. Balance shaft removal doesn't really add much vibration. At least somebody did it correctly by removing the rear shaft, leaving the front one in and removing the belt and tensioner. This is how both my cars have been for several years and both run awesome.

It's possible that the shavings you see are from one of the balance shaft bearings as well. Years ago, when I pulled the pan from 1051 to do the balance shaft removal, I found the same thing. Good timing I guess, as those bearings were in sad shape. All other bearings in the motor are just fine. Since the balance shafts spin at twice the RPM's as the rest of the rotating assembly, those bearings take a beating. Most people don't remove the balance shafts for power, but more for reliability. Getting those things out of there removes potential problems down the road.

great this explains why my car shook like hell I thought it was the damn urathane firewall mount /ubbthreads/images/graemlins/banghead.gif I do believe I liked this feature to keep the ratting in my car to a minumum... I might just try to fix this as well after I find out what happen to the motor first .. next is the head maby this sunday I can pull it off and see whats what...

The vibrating was probably caused by the urethane mount. Balance shaft removal doesn't really add much vibration. At least somebody did it correctly by removing the rear shaft, leaving the front one in and removing the belt and tensioner. This is how both my cars have been for several years and both run awesome.

It's possible that the shavings you see are from one of the balance shaft bearings as well. Years ago, when I pulled the pan from 1051 to do the balance shaft removal, I found the same thing. Good timing I guess, as those bearings were in sad shape. All other bearings in the motor are just fine. Since the balance shafts spin at twice the RPM's as the rest of the rotating assembly, those bearings take a beating. Most people don't remove the balance shafts for power, but more for reliability. Getting those things out of there removes potential problems down the road.

SmoothCustomer

Well-known member

Zomg a 1051 part in bad shape?!

turbowop

Well-known member

The road to efamousness isn't without a few bumps. /ubbthreads/images/graemlins/hsugh.gif

boostedinaz

Well-known member

I removed the balance shaft in the car when I had it and used all Mitsu parts and gaskets. The car only had slightly more vibration that when the shafts were in the car. The urethane mount would make a big difference in the amount of vibration that was transferred to the car.

I will say that the front cover was spotless when I put it back together. I cleaned and wiped down everything including the timing tensioner bracket, gears, plates that separate the Bshaft gear from the timing gear etc.... I also don't remember my dab of RTV being that messy but that was almost 3 years ago.

I will say that the front cover was spotless when I put it back together. I cleaned and wiped down everything including the timing tensioner bracket, gears, plates that separate the Bshaft gear from the timing gear etc.... I also don't remember my dab of RTV being that messy but that was almost 3 years ago.

Last edited:

toybreaker

iconoclast

- Joined

- Apr 30, 2006

- Messages

- 3,581

Damn, sounds like this car hasn't been treating you well. /ubbthreads/images/graemlins/frown.gif

The good news is by the time you get this figured out and back together, you will know a lot more about how things work.

Just getting the motor out and on a stand is more than many folks have done when faced with this problem, so don't be so hard on yourself.

... many folks just give up when faced with a siezed engine ...

If I could be so bold as to make a few suggestions, I would start by getting your work area organized.

Save some cardboard boxes and eggcartons from the recycle bin, they will come in handy

Go to a bulk store like Costco and get a bunch of ziplocs in various sizes, a couple of rubbermaid totes, some cheap tupperware type containers, some magic markers and a cheap notebook.

Take a picture of the area of the engine you are working on, and draw a picture on a piece of cardboard of the layout of the part, label it, and poke holes where the bolts go. As you remove a bolt, stick it thru the cardboard in the corresponding location and it'll be a lot easier to figure out where stuff goes when it's time to reassemble stuff. Make notes of any missing/damaged hardware, so it can be sourced.

Remove bolts one at a time, and transfer them to your cardboard templates.

Anytime a bolt doesn't "feel" right coming out, it should be noted on the cardboard template. There may be a problem with the threads in the block or whatever it threads into, and having it pinpointed on the template will allow you to remember what may need attention.

As the parts come off the motor, be sure to keep them organized.

Bagging the small stuff and labelling the bags with a magic marker will help.

If you dont know what a part is called, look it up in your factory service manual, so it can be labelled correctly. This will also allow you to learn the correct words/terminology for the pieces. This will make it eaier to ask good questions and get good answers when you run into something you dont understand.

Eggcartons are really good for keeping bearings organized. Open the carton, and draw a picture of the engine on the inside and as you remove the shells place them in the correct location. Keeping the upper and lower shells organized will help us troubleshoot your problems, especially when it comes to the rod bearings.

So, on to the troubleshooting ...

Read the vfaq on t-belts.

Before you go any further, see if you can get the lock pin to go back into the tensioner. It looks like the tensioner out a little too far already, but it's worth a shot. (you can use a small allen wrench for a lock pin) You will be replacing the tensioner, so it's no big deal if you can't get a lock pin in there. It just cuts down on the drama/sh*t moving when you're tearing the system down.

Go ahead and relax the tensioner pulley bolt.

Things may "jump" a little, so keep your hands clear of the belt!

Slide the belt off.

Try and turn the oil pump pulley. Note if it turns freely.

Now, since you have looked down the spark plug holes, you know if any of the pistons are at top dead center.

If you have any at tdc, you will have to be carefull with the next couple of steps as you can run a valve into a piston when you turn a cam, or you can run a piston into a valve when you turn the crank.

If none of the pistons are close to tdc, you can spin the cams, one at a time, to see if they are rotate. Be carefull as they will "snap" forward aggressively when they go over the top of the lobes. (I usually use a ratchet, so they can spin away without busting a knuckle.)

If the cams both turn, that leaves the crank.

Try and turn the crank but don't turn it very far! as you will run into valves if you get up close to tdc.

Please post up what doesn't turn, and we will be able to get you better advice on how to procceed.

As an aside, I used to really suck at posting on the intraweb. /ubbthreads/images/graemlins/blush.gif

... now that I've found the shift and enter keys, I break things down into paragraphs so it's easier to read ...

(can't do much abou the content of my posts tho /ubbthreads/images/graemlins/rofl.gif )

... don't sweat the grammar and spelling, just do the best you can ...

If you make an effort to make things more readable, you'll get a lot better response to your threads, and the asshats won't be dogging your posts.

And, lastly, you're lucky to be living in area with some really saavy members.

They are all busy with their own lives and whatnot, but if your fridge is stocked with frosty cold libations, they will come and help when they can

The good news is by the time you get this figured out and back together, you will know a lot more about how things work.

Just getting the motor out and on a stand is more than many folks have done when faced with this problem, so don't be so hard on yourself.

... many folks just give up when faced with a siezed engine ...

If I could be so bold as to make a few suggestions, I would start by getting your work area organized.

Save some cardboard boxes and eggcartons from the recycle bin, they will come in handy

Go to a bulk store like Costco and get a bunch of ziplocs in various sizes, a couple of rubbermaid totes, some cheap tupperware type containers, some magic markers and a cheap notebook.

Take a picture of the area of the engine you are working on, and draw a picture on a piece of cardboard of the layout of the part, label it, and poke holes where the bolts go. As you remove a bolt, stick it thru the cardboard in the corresponding location and it'll be a lot easier to figure out where stuff goes when it's time to reassemble stuff. Make notes of any missing/damaged hardware, so it can be sourced.

Remove bolts one at a time, and transfer them to your cardboard templates.

Anytime a bolt doesn't "feel" right coming out, it should be noted on the cardboard template. There may be a problem with the threads in the block or whatever it threads into, and having it pinpointed on the template will allow you to remember what may need attention.

As the parts come off the motor, be sure to keep them organized.

Bagging the small stuff and labelling the bags with a magic marker will help.

If you dont know what a part is called, look it up in your factory service manual, so it can be labelled correctly. This will also allow you to learn the correct words/terminology for the pieces. This will make it eaier to ask good questions and get good answers when you run into something you dont understand.

Eggcartons are really good for keeping bearings organized. Open the carton, and draw a picture of the engine on the inside and as you remove the shells place them in the correct location. Keeping the upper and lower shells organized will help us troubleshoot your problems, especially when it comes to the rod bearings.

So, on to the troubleshooting ...

Read the vfaq on t-belts.

Before you go any further, see if you can get the lock pin to go back into the tensioner. It looks like the tensioner out a little too far already, but it's worth a shot. (you can use a small allen wrench for a lock pin) You will be replacing the tensioner, so it's no big deal if you can't get a lock pin in there. It just cuts down on the drama/sh*t moving when you're tearing the system down.

Go ahead and relax the tensioner pulley bolt.

Things may "jump" a little, so keep your hands clear of the belt!

Slide the belt off.

Try and turn the oil pump pulley. Note if it turns freely.

Now, since you have looked down the spark plug holes, you know if any of the pistons are at top dead center.

If you have any at tdc, you will have to be carefull with the next couple of steps as you can run a valve into a piston when you turn a cam, or you can run a piston into a valve when you turn the crank.

If none of the pistons are close to tdc, you can spin the cams, one at a time, to see if they are rotate. Be carefull as they will "snap" forward aggressively when they go over the top of the lobes. (I usually use a ratchet, so they can spin away without busting a knuckle.)

If the cams both turn, that leaves the crank.

Try and turn the crank but don't turn it very far! as you will run into valves if you get up close to tdc.

Please post up what doesn't turn, and we will be able to get you better advice on how to procceed.

As an aside, I used to really suck at posting on the intraweb. /ubbthreads/images/graemlins/blush.gif

... now that I've found the shift and enter keys, I break things down into paragraphs so it's easier to read ...

(can't do much abou the content of my posts tho /ubbthreads/images/graemlins/rofl.gif )

... don't sweat the grammar and spelling, just do the best you can ...

If you make an effort to make things more readable, you'll get a lot better response to your threads, and the asshats won't be dogging your posts.

And, lastly, you're lucky to be living in area with some really saavy members.

They are all busy with their own lives and whatnot, but if your fridge is stocked with frosty cold libations, they will come and help when they can

^^ Wow! Now that's info. Nice... /ubbthreads/images/graemlins/applause.gif

good post toybreaker. Keep us updated on what you find.