Taken from ARP'S website.

Engaged Thread

An additional factor must be taken into account in defining the bolt configuration: the length of engaged thread. If too few threads are engaged, the threads will shear at loads that are lower than the strength of the bolt. As a practical matter, the thread length is always selected so that the thread shear strength is -significantly greater than the bolt tension strength.

This problem is especially important in bolts used in aluminum rods because of the fact that the shear strength of aluminum is much lower than the shear strength of steel.

Grodens instructions

R&R instructions

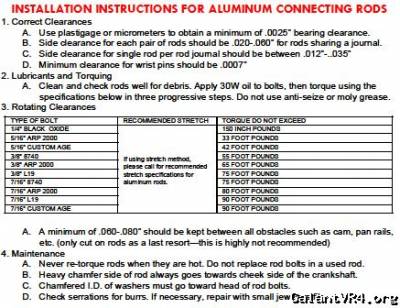

Taken from MGP website

Technical Advice

Torque Procedures and Specifications

The method need to achieve proper torque and fastener stretch will be identical for all connecting rods manufactured within our facility. The torque rating will be dictated by the number designated on the head of the fastener. Compare the number on the had of the fastener with the list below for proper torque specifications.

Before assembly in the engine takes place the connecting rods must be taken apart, cleansed and dried with compressed air. It is imperative that the serrations on the rod cap and rod body be free of dirt, oil and debris. Utilize extra caution when handling the cap and body, as the serrations must remain undamaged for proper assembly. Once in the engine place the rod cap on the rod body. Lubricate the threads of each fastener liberally with fifty(50) weight motor oil and thread the fastener into connecting rod until the head of the fastener just contacts the washer assembly. The use of fifty(50) weight motor oil is critical, as the use of any other lubricant will lead to improper fastener stretch. Using a slow and steady pass with the wrench torque each rod bolt. The "Step-Torque" method is an IMPROPER technique DO NOT USE this technique it will lead to improper fastener stretch. The use of a stretch gauge can be used to guarantee proper fastener torque and stretch.

Fastener #1003: 105/ft/lbs Fastener Stretch: 0.007"-0.0075"

Fastener #1004: 85/ft/lbs Fastener Stretch: 0.007"-0.0075"

Fastener #1008: 65/ft/lbs Fastener Stretch: 0.006"-0.0065"

Fastener #1009: 105/ft/lbs Fastener Stretch: 0.007"-0.0075"

Clearances

Per our recommendation the vertical clearance on rods for drag racing use should be .003-.0035" and the side clearance should be a minimum of .015" and maximum of .020". These specifications are for naturally aspirated engines for endurance applications. We have seen no advantage to opening up clearances beyond recommendations.

For nitrous-oxide applications our recommendations are the same as for naturally aspirated engines.

More Assistance

If we may be of assistance in answering any other questions please do not hesitate to contact us at 719-219-3017 or fax 719-219-3078. We are very happy to help in any way possible.